EGAF Aphonic grilles

Description

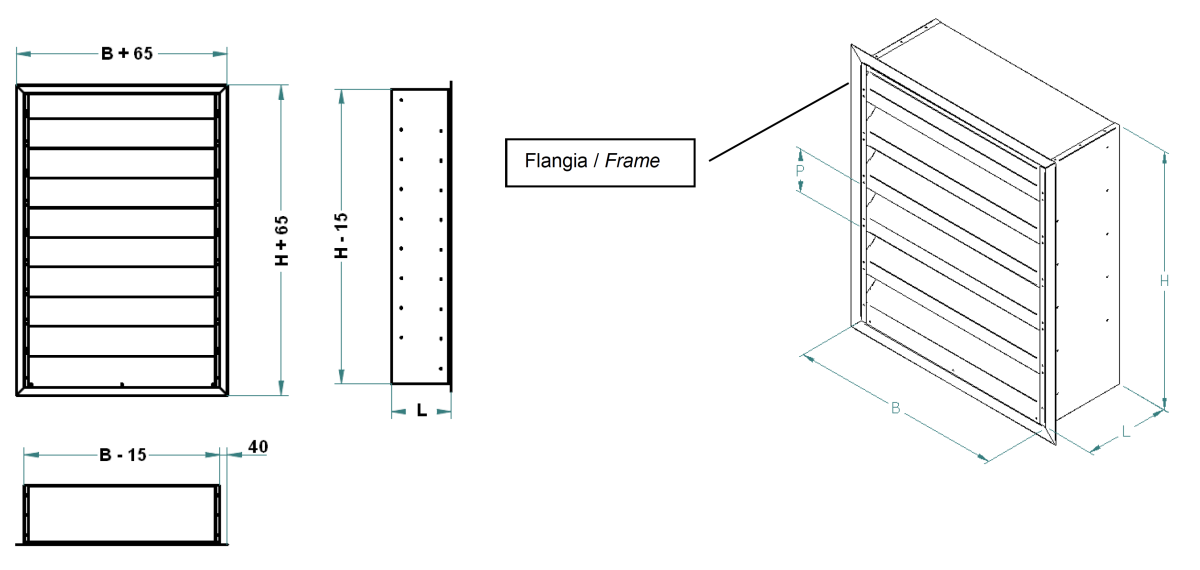

Galvanized steel aphonic grilles for both supply and exhaust air, with blades inclined by 45°.

Characteristics

The frame is made of galvanised steel sheet, with a standard depth of 300 mm. Blades with a 150 mm pitch made of galvanised steel sheet, shaped to contain the sound-absorbing material. Inside coated with micro-stretched mesh.

40 mm galvanised steel perimeter flange.

Bird mesh on request.

Sound-absorbing material with high density mineral wool, in fire reaction Class “0” (non-combustible) (Italian Ministerial Decree 26/06/1984).

Maximum operating temperature: 250°C. Maximum operating pressure: 2,000 Pa.

40 mm galvanised steel perimeter flange.

Bird mesh on request.

Sound-absorbing material with high density mineral wool, in fire reaction Class “0” (non-combustible) (Italian Ministerial Decree 26/06/1984).

Maximum operating temperature: 250°C. Maximum operating pressure: 2,000 Pa.

Installation

Assembly with screws on 40 mm flange or directly on duct.

Model

EGAF thickness 100mm;

EGAF thickness 150mm;

EGAF thickness 200mm;

EGAF thickness 300mm;

EGAF thickness 600mm (300mm + 300mm).

EGAF thickness 150mm;

EGAF thickness 200mm;

EGAF thickness 300mm;

EGAF thickness 600mm (300mm + 300mm).

On request

-Stainless steel or aluminium frames

-Possibility of supplying painted product.

-L depths different from the standard.

-Possibility of supplying painted product.

-L depths different from the standard.

Dimensions and effective cross-sections:

| H (mm) | |||||||||||

| B (mm) | 450 | 600 | 750 | 900 | 1050 | 1200 | 1350 | 1500 | 1650 | 1800 | 1950 |

| sezione efficace m² | |||||||||||

| 300 | 0,02 | 0,05 | 0,06 | 0,09 | 0,10 | 0,12 | 0,13 | 0,16 | 0,17 | 0,20 | 0,21 |

| 400 | 0,03 | 0,07 | 0,09 | 0,12 | 0,14 | 0,17 | 0,19 | 0,22 | 0,24 | 0,28 | 0,29 |

| 500 | 0,04 | 0,09 | 0,11 | 0,16 | 0,18 | 0,22 | 0,24 | 0,29 | 0,31 | 0,36 | 0,38 |

| 600 | 0,05 | 0,11 | 0,14 | 0,19 | 0,22 | 0,27 | 0,30 | 0,35 | 0,38 | ||

| 700 | 0,06 | 0,13 | 0,16 | 0,23 | 0,26 | 0,32 | 0,35 | 0,42 | 0,45 | ||

| 800 | 0,07 | 0,16 | 0,19 | 0,28 | 0,30 | 0,37 | 0,41 | 0,48 | 0,52 | ||

| 900 | 0,08 | 0,17 | 0,21 | 0,30 | 0,34 | 0,42 | 0,48 | 0,55 | |||

| 1000 | 0,09 | 0,19 | 0,24 | 0,33 | 0,38 | 0,47 | 0,52 | 0,61 | |||

| 1100 | 0,10 | 0,21 | 0,26 | 0,37 | 0,42 | 0,52 | 0,57 | 0,68 | |||

| 1200 | 0,11 | 0,23 | 0,29 | 0,40 | 0,46 | 0,57 | 0,63 | ||||

| 1300 | 0,12 | 0,25 | 0,31 | 0,44 | 0,50 | 0,62 | 0,68 | ||||

| 1400 | 0,13 | 0,27 | 0,34 | 0,47 | 0,54 | 0,67 | 0,74 | ||||

| 1500 | 0,14 | 0,29 | 0,36 | 0,51 | 0,58 | 0,72 | |||||

| 1600 | 0,15 | 0,31 | 0,39 | 0,54 | 0,62 | 0,77 | |||||

| 1700 | 0,16 | 0,33 | 0,41 | 0,58 | 0,66 | 0,82 | |||||

| 1800 | 0,17 | 0,35 | 0,44 | 0,61 | 0,70 | ||||||

Technical data:

| H (mm) | |||||||||||

| B (mm) | 450 | 600 | 750 | 900 | 1050 | 1200 | 1350 | 1500 | 1650 | 1800 | 1950 |

| Portata aria massima consigliata in m³/h e perdita di carico pari a 68 Pa. | |||||||||||

| 300 | 680 | 1350 | 1690 | 2370 | 2710 | 3380 | 3720 | 4400 | 4730 | 5410 | 5750 |

| 400 | 950 | 1900 | 2380 | 3330 | 3810 | 1760 | 5240 | 6190 | 6670 | 7620 | 8100 |

| 500 | 1230 | 2460 | 3070 | 4300 | 4910 | 6140 | 6760 | 7990 | 8600 | 9830 | 10440 |

| 600 | 1500 | 3010 | 3760 | 5270 | 6020 | 7520 | 8280 | 9780 | 10530 | ||

| 700 | 1780 | 3560 | 4450 | 6230 | 7120 | 8900 | 9790 | 11570 | 12460 | ||

| 800 | 2060 | 4110 | 5140 | 7200 | 8230 | 10280 | 11310 | 13370 | 14400 | ||

| 900 | 2330 | 4670 | 5830 | 8160 | 9330 | 11660 | 12830 | 15160 | |||

| 1000 | 2610 | 5220 | 6520 | 9130 | 10440 | 13040 | 14350 | 16960 | |||

| 1100 | 2880 | 5770 | 7210 | 10100 | 11540 | 14420 | 15670 | 18750 | |||

| 1200 | 3160 | 6320 | 7900 | 11060 | 12640 | 15810 | 17390 | ||||

| 1300 | 3440 | 6870 | 8590 | 12030 | 13750 | 17190 | 18900 | ||||

| 1400 | 3710 | 7430 | 9280 | 13000 | 14850 | 18570 | 20420 | ||||

| 1500 | 3990 | 7980 | 9970 | 13960 | 15960 | 19950 | |||||

| 1600 | 4270 | 8530 | 10660 | 14930 | 17060 | 21330 | |||||

| 1700 | 4540 | 9080 | 11350 | 15890 | 18170 | 22710 | |||||

| 1800 | 4820 | 9630 | 12040 | 16860 | 19270 | ||||||

Insertion attenuation

The insertion attenuation is the ability of the aphonic grille to reduce the noise produced by the ventilation system to the outside.

| Models | Hz | 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

| EGAF spessore 100mm | [dB] | 1 | 2 | 3 | 5 | 8 | 9 | 9 | 10 |

| EGAF spessore 150mm | [dB] | 2 | 3 | 3 | 7 | 9 | 11 | 10 | 11 |

| EGAF spessore 200mm | [dB] | 3 | 4 | 4 | 7 | 11 | 13 | 12 | 12 |

| EGAF spessore 300mm | [dB] | 3 | 4 | 5 | 9 | 12 | 15 | 14 | 15 |

| EGAF spessore 600mm (300mm + 300mm) | [dB] | 4 | 5 | 9 | 15 | 22 | 27 | 25 | 24 |

Soundproofing power

Soundproofing power is the ability of an element to prevent sound waves from passing from one room to another. It characterises the acoustic features of dividers and partitions, as well as of aphonic grilles installed on walls. Its soundproofing power complies with UNI EN ISO 140 - 3:2006 and UNI EN ISO 717 -1:2007.

| Models | Hz | 125 | 250 | 500 | 1000 | 2000 | 4000 | Rw |

| EGAF spessore 100mm | [dB] | 2 | 4 | 7 | 9 | 9 | 10 | 9,0 |

| EGAF spessore 150mm | [dB] | 3 | 5 | 7 | 10 | 11 | 11 | 10,0 |

| EGAF spessore 200mm | [dB] | 5 | 6 | 7 | 12 | 15 | 14 | 12,0 |

| EGAF spessore 300mm | [dB] | 6 | 7 | 10 | 18 | 22 | 23 | 16,0 |

| EGAF spessore 600mm (300mm + 300mm) | [dB] | 6 | 10 | 17 | 24 | 30 | 27 | 21,8 |

Pressure drops

Pressure drops in EGAF series aphonic grilles depend on the air velocity inside the duct and also on the direction of the air. In fact, pressure drops are generally greater in supply than in exhaust.

| Models | m/s | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 |

| EGAF spessore 100mm | Pa | 5 | 19 | 43 | 75 | 117 | 167 | 293 | 453 |

| EGAF spessore 150mm | Pa | 6 | 23 | 52 | 90 | 140 | 200 | 351 | 544 |

| EGAF spessore 200mm | Pa | 7 | 27 | 60 | 106 | 163 | 233 | 410 | 634 |

| EGAF spessore 300mm | Pa | 8 | 31 | 68 | 120 | 186 | 266 | 467 | 723 |

| EGAF spessore 600mm (300mm + 300mm) | Pa | 13 | 53 | 121 | 218 | 344 | 499 | 896 | 1412 |